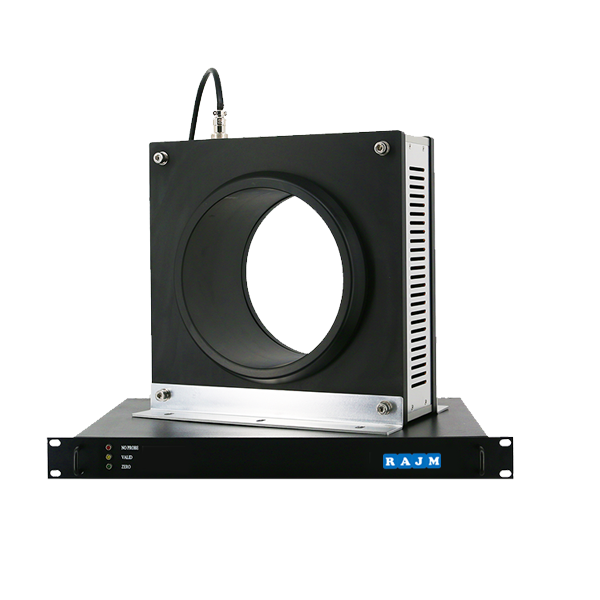

Today we will introduce a recent popular product of RenAn – 25,000A high current DC current transducer with 10ppm accuracy.

This 25,000A high-current DC transducers has a high-end appearance design, the coil and the control box are separated, black and silver-gray are matched, advanced and textured, and a custom-made convenient cart is convenient and efficient to use.

1. Product Introduction

RenAn high current sensor adopts the principle of fluxgate technology, and realizes current detection through classical control theory instead of conventional chip induction. It is not sensitive to the external environment, and basically has no temperature drift and zero drift; its magnetic core does not require Opening cutting, which has small magnetic resistance, high magnetic flux stability, high sensor detection accuracy, high sensitivity and fast response speed.

In terms of technical indicators and performance, RenAn high-precision high-current sensors have become the top-end products on the market.

RenAn’s high-precision high-current sensor has a maximum accuracy of 10ppm, and can measure DC, AC, and pulse currents, which can fully meet users’ various high-accuracy electrical measurement needs. The product has a status indication function and has better safety; it has a large aperture of 120mm to 200mm for the cable to pass through. For the special needs of user-defined scenarios, RenAn can provide solutions that meet customers’ customized measurement scenarios.

2. Product Specifications

❖ High precision: up to 10ppm

❖ Excellent linearity: 10ppm

❖ Bandwidth (-3dB): 20kHz

❖ Response speed: 10uS

❖ High stability: 0.1ppm/k (temperature) 0.2ppm/month (time)

❖ Large aperture: 60mm/ 90mm/120mm / 160mm / 200mm/ 250mm

❖ Operating temperature range: -40~+85 °C

❖ Power supply: 220V AC

❖ Rich models: 8,000A/10,000A/15,000A /20,000A / 25,000A

the catalog of High Current Transducer

| Model Number | Nominal Range (A) | Maximum Range (A) | Ration | Secondary Output (A) | Bandwidth (kHz) | Accuracy (ppm) | Linearity (ppm) | Power Supply (V) | Aperture (mm) | Housing Type | Datasheet |

|---|---|---|---|---|---|---|---|---|---|---|---|

| RAPT1000-D60S | ±1000 | ±1200 | 1000:1 | ±1.0 | 100 | 10 | 2 | AC220V | 60 | Split | Request Datasheet & Quote |

| RAPT2000-D60S | ±2000 | ±2400 | 2000:1 | ±1.0 | 50 | 10 | 2 | AC220V | 60 | Split | Request Datasheet & Quote |

| RAPT2000-D90S | ±2000 | ±2400 | 2000:1 | ±1.0 | 50 | 10 | 2 | AC220V | 90 | Split | Request Datasheet & Quote |

| RAPT3000-D90S | ±3000 | ±3600 | 3000:1 | ±1.0 | 30 | 10 | 2 | AC220V | 90 | Split | Request Datasheet & Quote |

| RAPT3000-D120S | ±3000 | ±3600 | 3000:1 | ±1.0 | 30 | 10 | 2 | AC220V | 120 | Split | Request Datasheet & Quote |

| RAPT3000-D160S | ±3000 | ±3600 | 3000:1 | ±1.0 | 30 | 10 | 2 | AC220V | 160 | Split | Request Datasheet & Quote |

| RAPT4000-D90S | ±4000 | ±4800 | 4000:1 | ±1.0 | 20 | 10 | 2 | AC220V | 90 | Split | Request Datasheet & Quote |

| RAPT4000-D120S | ±4000 | ±4800 | 4000:1 | ±1.0 | 20 | 10 | 2 | AC220V | 120 | Split | Request Datasheet & Quote |

| RAPT4000-D160S | ±4000 | ±4800 | 4000:1 | ±1.0 | 20 | 10 | 2 | AC220V | 160 | Split | Request Datasheet & Quote |

| RAPT5000-D90S | ±5000 | ±6000 | 5000:1 | ±1.0 | 20 | 10 | 2 | AC220V | 90 | Split | Request Datasheet & Quote |

| RAPT5000-D120S | ±5000 | ±6000 | 5000:1 | ±1.0 | 20 | 10 | 2 | AC220V | 120 | Split | Request Datasheet & Quote |

| RAPT5000-D160S | ±5000 | ±6000 | 5000:1 | ±1.0 | 20 | 10 | 2 | AC220V | 160 | Split | Request Datasheet & Quote |

| RAPT6000-D90S | ±6000 | ±7200 | 5000:1 | ±1.2 | 20 | 10 | 2 | AC220V | 90 | Split | Request Datasheet & Quote |

| RAPT6000-D120S | ±6000 | ±7200 | 5000:1 | ±1.2 | 20 | 10 | 2 | AC220V | 120 | Split | Request Datasheet & Quote |

| RAPT6000-D160S | ±6000 | ±7200 | 5000:1 | ±1.2 | 20 | 10 | 2 | AC220V | 160 | Split | Request Datasheet & Quote |

| RAPT8000-D120S | ±8000 | ±9600 | 5000:1 | ±1.6 | 20 | 10 | 2 | AC220V | 120 | Split | Request Datasheet & Quote |

| RAPT8000-D160S | ±8000 | ±9600 | 5000:1 | ±1.6 | 20 | 10 | 2 | AC220V | 160 | Split | Request Datasheet & Quote |

| RAPT8000-D200S | ±8000 | ±9600 | 5000:1 | ±1.6 | 20 | 10 | 2 | AC220V | 200 | Split | Request Datasheet & Quote |

| RAPT10K-D120S | ±10000 | ±12000 | 5000:1 | ±2.0 | 10 | 10 | 2 | AC220V | 120 | Split | Request Datasheet & Quote |

| RAPT10K-D160S | ±10000 | ±12000 | 5000:1 | ±2.0 | 10 | 10 | 2 | AC220V | 160 | Split | Request Datasheet & Quote |

| RAPT10K-D200S | ±10000 | ±12000 | 5000:1 | ±2.0 | 10 | 10 | 2 | AC220V | 200 | Split | Request Datasheet & Quote |

| RAPT15K-D160S | ±15000 | ±18000 | 5000:1 | ±3.0 | 10 | 10 | 2 | AC220V | 160 | Split | Request Datasheet & Quote |

| RAPT15K-D160S | ±15000 | ±18000 | 6400:1 | ±2.34375 | 10 | 10 | 2 | AC220V | 160 | Split | Request Datasheet & Quote |

| RAPT15K-D200S | ±15000 | ±18000 | 6400:1 | ±2.34375 | 10 | 10 | 2 | AC220V | 200 | Split | Request Datasheet & Quote |

| RAPT20K-D200S | ±20000 | ±24000 | 6400:1 | ±3.125 | 8 | 10 | 2 | AC220V | 200 | Split | Request Datasheet & Quote |

| RAPT20K-D250S | ±20000 | ±24000 | 6400:1 | ±3.125 | 8 | 10 | 2 | AC220V | 250 | Split | Request Datasheet & Quote |

| RAPT20K-D250S | ±20000 | ±24000 | 8000:1 | ±2.5 | 5 | 10 | 2 | AC220V | 250 | Split | Request Datasheet & Quote |

| RAPT25K-D250S | ±25000 | ±30000 | 8000:1 | ±3.125 | 5 | 10 | 2 | AC220V | 250 | Split | Request Datasheet & Quote |

3. Product Applications - High Current Transducers

High current current transducer applications can measure high DC & AC current . These transducers generate a signal whose magnitude is proportional to the current being measured; this signal can be transmitted with forms of voltage, current and RS485. It’s important to note that high current DC current transducers are useful in many contexts, including:

In electric vehicles (EVs), high current DC current transducers track the charging and discharging of batteries, as well as the operation of motors and the distribution of electricity.

High current transducers are used to monitor power generation, conversion, and distribution in renewable energy systems like solar power plants, wind farms, and others.

High current transducers are used in power electronics to measure and regulate high currents in high-voltage power transmission systems, including power converters and inverters.

These transducers are used in welding, motor control, power supplies, and robotics among other industrial applications to measure and regulate high currents for the purpose of ensuring the security and efficacy of these processes.

High current DC current transducers are used in smart grids, energy storage systems, and facility management to track and optimise power usage for maximum efficiency and savings.

Overcurrent conditions in high current circuits can be detected by transducers, allowing protective measures to be taken to prevent equipment failure.

In the telecommunications industry, high current transducers can be used to keep data centres and other network nodes running smoothly and reliably by monitoring and controlling the flow of power.

High current transducers are used to monitor and manage power distribution in railway systems and other electric transportation systems to guarantee safe and efficient operations.

High current transducers are a type of test and measurement equipment that is used in a wide variety of R&D settings to measure and analyse high current levels in different types of electrical systems and devices.

In large-scale battery systems, like those used for grid energy storage or backup power systems, high current transducers are used to monitor charging, discharging, and overall health.

As you can see, the uses for high current DC current transducers are practically endless. As a result of their ability to precisely monitor and record high current levels, they are indispensable to many sectors and systems that depend on streamlined power distribution and management.

PV Inverter Testing System

Wind Turbine Testing System

Ion Accelerator